Maintenance? Starts with mobile

SAP PM/EAM is the ideal system for managing maintenance and repair tasks (maintenance plans, maintenance orders, and much more) in manufacturing companies. However, maintenance is only economical if digitalization also includes the workers.

The MAINTENANCE SUITE by T.CON add-on bundle closes these gaps without any system disruption. It is fully integrated into your familiar SAP environment and ensures higher data quality and timeliness as well as smooth end-to-end processes.

- Damage-oriented

Damage reports from the machine via ENTERPRISE LOGBOOK by T.CON - Preventive

According to maintenance plan - Condition-oriented

Measurement data-oriented QM inspections (e.g. consumption reports)

Maintenance from a single source. Maintenance Suite

The ideal duo for planning and processing.

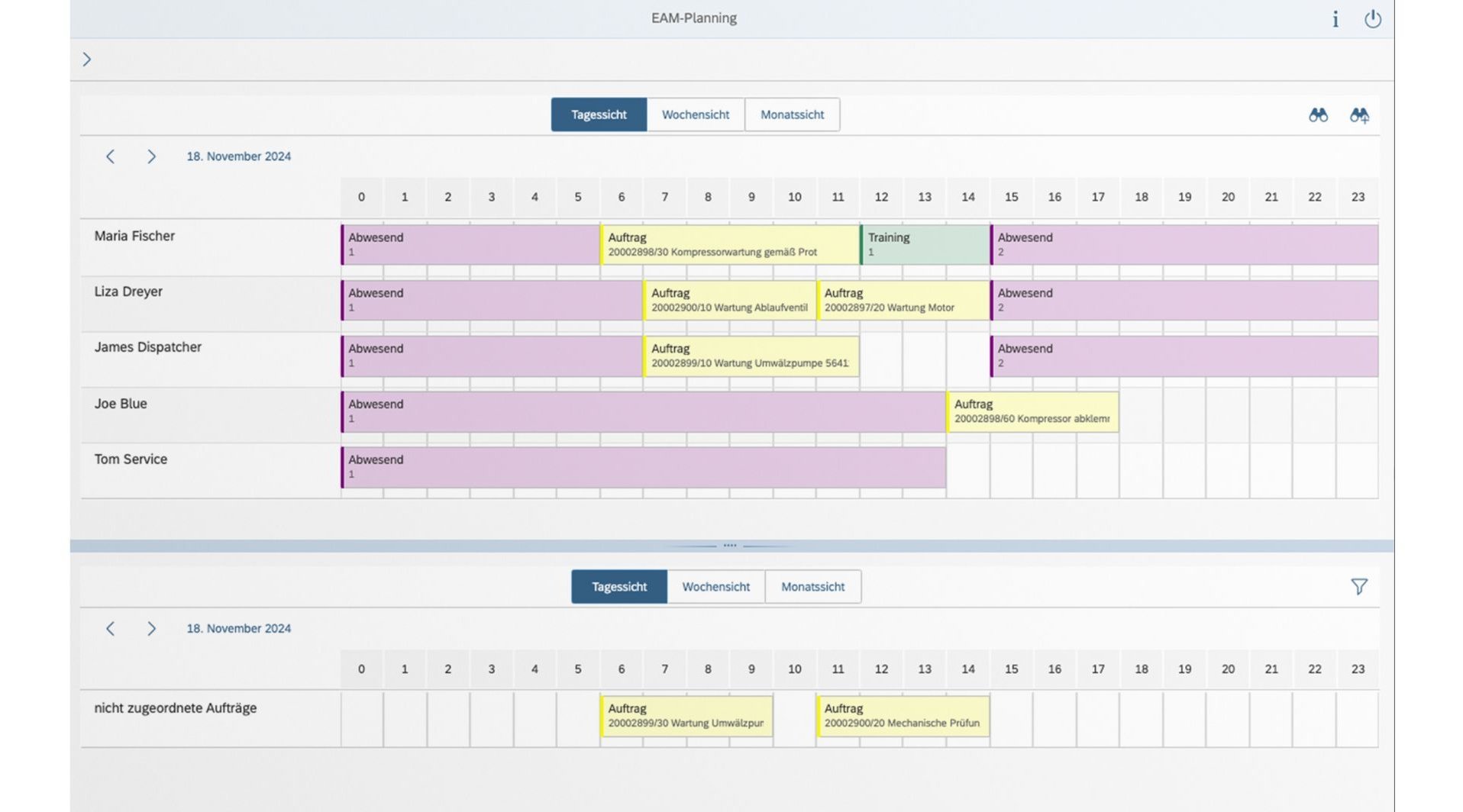

MAINTENANCE PLANNING

The graphical user interface for planning human resources saves time, is flexible, and intuitive to use.

Decide for yourself whether you want to use the lean and cost-effective MAINTENANCE PLANNING module or the sophisticated resource planning function directly from SAP.

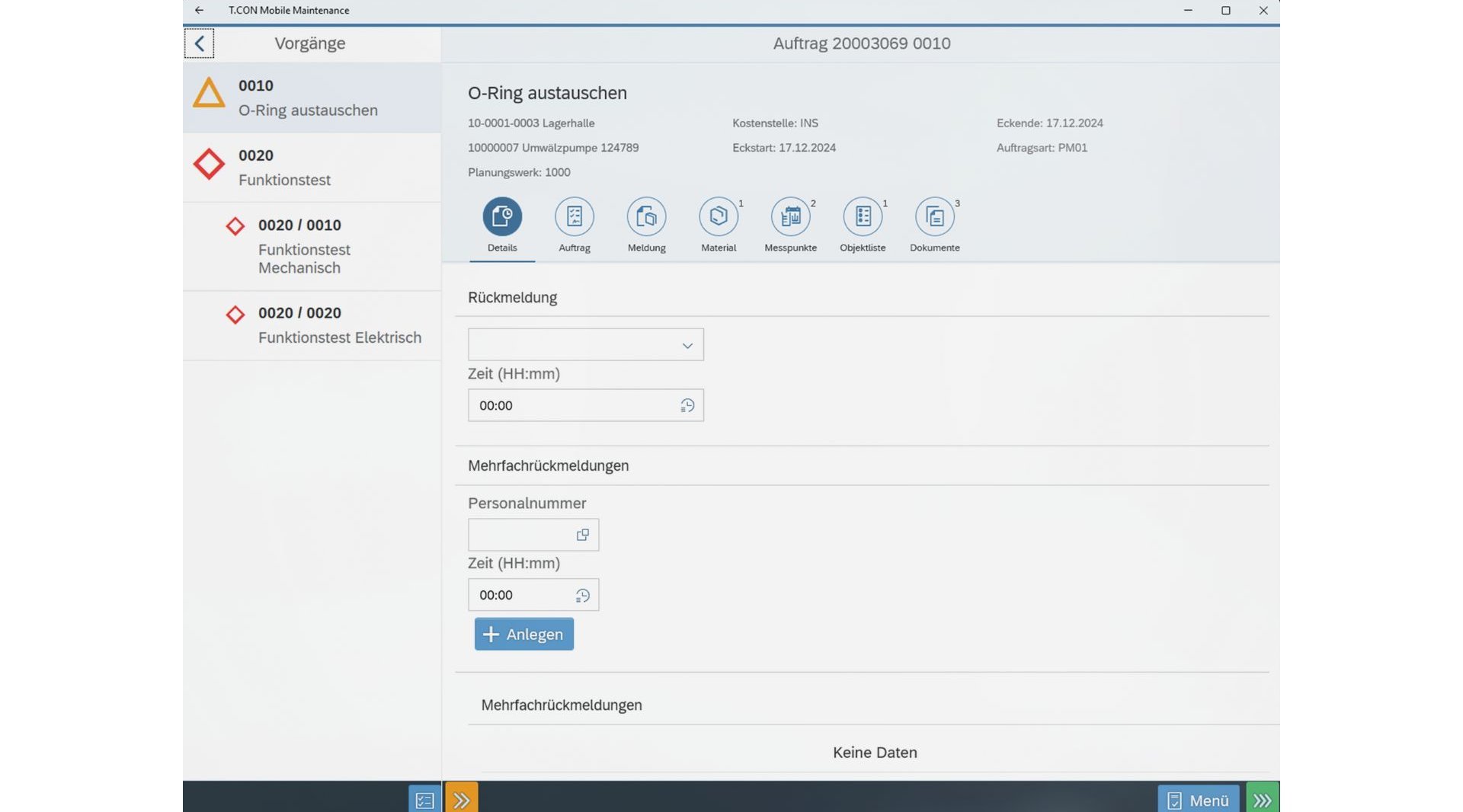

MOBILE MAINTENANCE

Mobile, offline-ready, intuitive. Work where maintenance happens — even without Wi-Fi. The MOBILE MAINTENANCE app runs on any device, works offline, and automatically synchronizes data with your SAP system. Intuitive operation in SAP UI5 design, lightning-fast machine identification via RFID or barcode included.

Your added value with MAINTENANCE SUITE

Production boost for the entire manufacturing process

- Optimized maintenance processes

- Improved workflows

- Higher data quality

- Efficient maintenance leads to higher productivity throughout the entire manufacturing process

More enjoyment at work

- Avoid incorrect entries with Auto ID and value helpers

- Fewer careless errors thanks to direct data entry on site

- No transmission errors, as there are no media breaks such as paper to SAP

- Documentation of damage cases by photo

- Information is always available where it is needed

- Data is posted directly in the SAP system. In case offline usage alternatively with a short delay

- Access to required data at any time

- No double data entry (paper/SAP)

- Modern user interface

- High acceptance thanks to working with contemporary media such as tablets and smartphones

- Fast data capture with simple masks, value helpers, pre- and background assignment of data

- Neither paper print outs nor paper processing

- Complex bookings are reduced to clear and simple masks

- Maintenance and fault processes are accelerated

A glance at MAINTENANCE SUITE

Further T.CON solutions for manufacturing

Our idea of modularity goes even further: T.CON strives to always provide the best SAP-based system for every customer. From individual requirements for a single application to a complete ERP and MES system landscape.