With ongoing skills shortages, it’s ever more essential for enterprises to have intuitive, easy to use systems. After all you can’t guarantee that new hires will be familiar with complex MES systems – and it’s also harder to source training for them. As a result, there’s a growing focus on worker-centric models, which are based around the machine itself, not the system. That means a transition toward exception-based working methods, with clear recommendations for action.

The challenges of production for the next generation

These requirements cannot be met without digital, networked production. An MES system is the interface for all data streams and is therefore indispensable!

Join the digital revolution, and boost your efficiency and market resilience. You need to implement real-time, data-driven decision-making. You need technical structures that facilitate seamless communication between manufacturing stages. You need process integration between machines, systems and services. That’s how you create a basis for working optimally on the shop floor – and create a real competitive advantage.

Environmental social governance (ESG) has long been a moral imperative; with the EU CSR directive, it is now also a compliance requirement. But without the right software, it’s impossible to guarantee seamless data recording and an accurate carbon footprint for your production. MES CAT allows for data to be recorded at every relevant point, ensuring your architecture is fully fit for the next generation. In fact, the tool can do more than just create a basis for your sustainability reporting. Use it to actively steer your production based on sustainability criteria.

Our products speak SAP fluently

As an SAP Gold Partner, T.CON demonstrates comprehensive expertise and a high level of competence in the implementation, customization, and consulting of SAP products. T.CON's own products also benefit from this expertise and can be seamlessly integrated into any SAP system landscape.

- No “off-chain” dark processes

Instead, there is a constant exchange of information between the systems. Idle inventory due to long production cycles and missing consumption reports to the ERP? Not with MES CAT! - No more system breaks for users. Familiar environment

100 % SAP ERP-integrated MES application. Ideal conditions for seamless communication with all systems and modules. Including planning and logistics!

The right MES for every need

Modularity & scalability

Flexible and future-proof

At T.CON, MES solutions are not rigid monoliths. Our aim is to implement the best MES for your needs, and this can only be achieved with a consistently modular approach that begins with the selection of the MES core system.

MES CAT 7 PRIVATE

For companies that want to continue relying on a tried-and-tested industry solution from a specialist in the future, MES CAT 7 PRIVATE offers the perfect balance of independence and technological advantages without having to sacrifice applications and usability specifically designed for large-scale production. You remain flexible without sacrificing the strengths of a modern platform application. At the same time, MES CAT 7 PRIVATE enables step-by-step transformation and offers an ideal solution for customers who are not yet ready to take the big step into a complete SAP Public Cloud environment but still want to be future-proof.

The cloud era for area-based manufacturing begins here

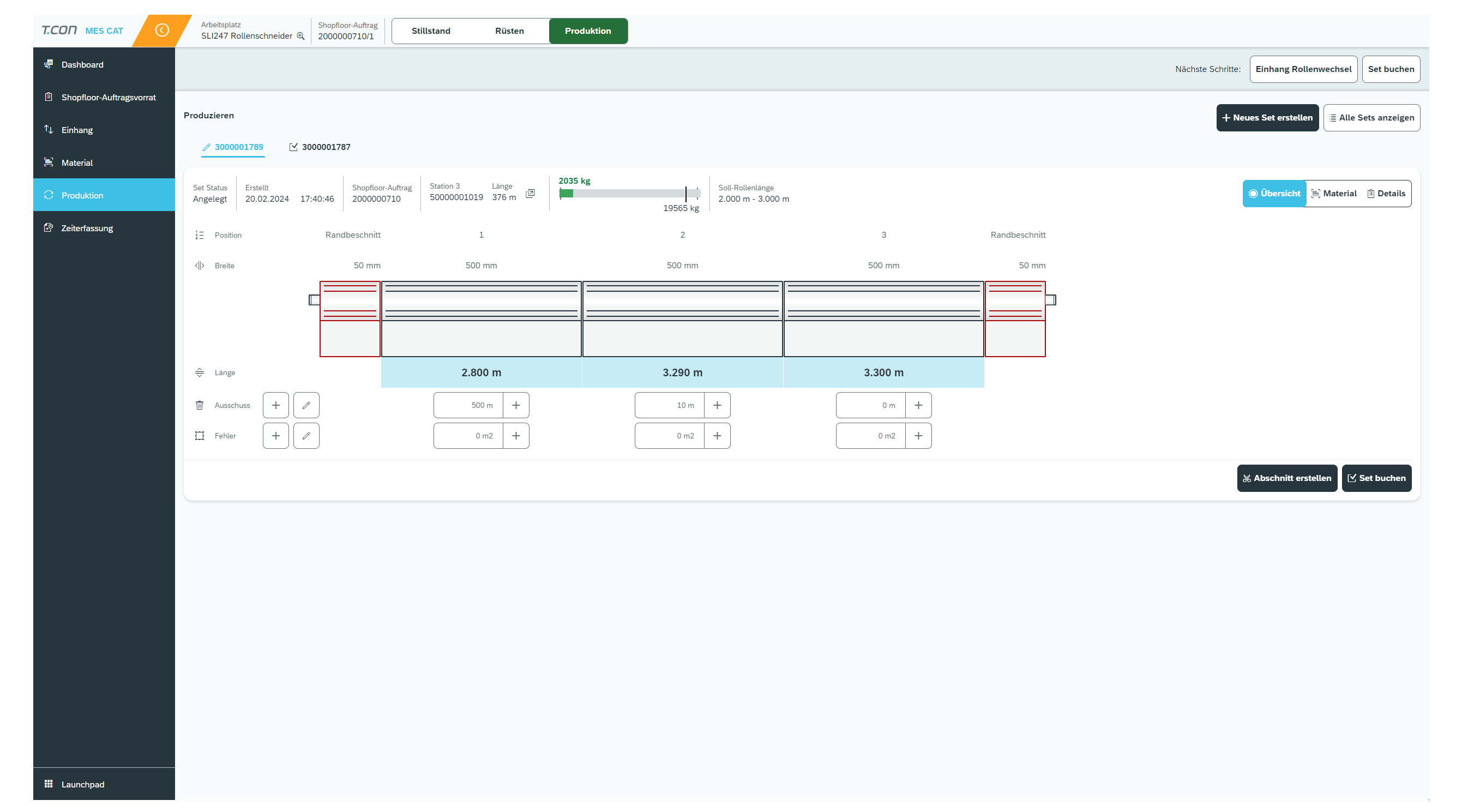

The best MES for reel and sheet production

Production methods may look similar from one business segment to the next, but no two processes are the same, and no two companies have exactly the same needs from their MES. The MES CAT standard templates are a tried-and-tested basis that can be flexibly adapted to the specific needs of your industry.

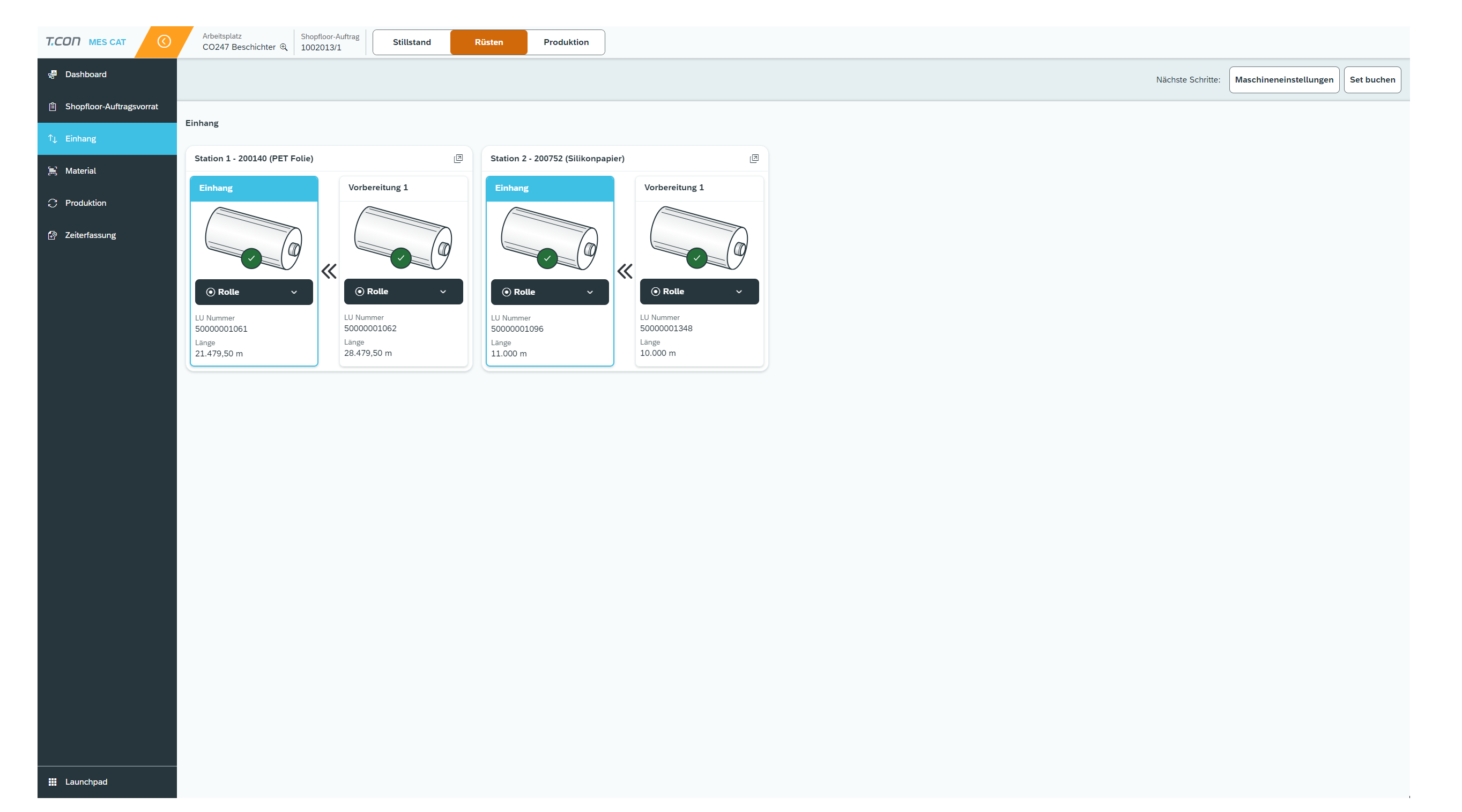

- With predefined machine types

- With your specialist terminology

- With predefined processes

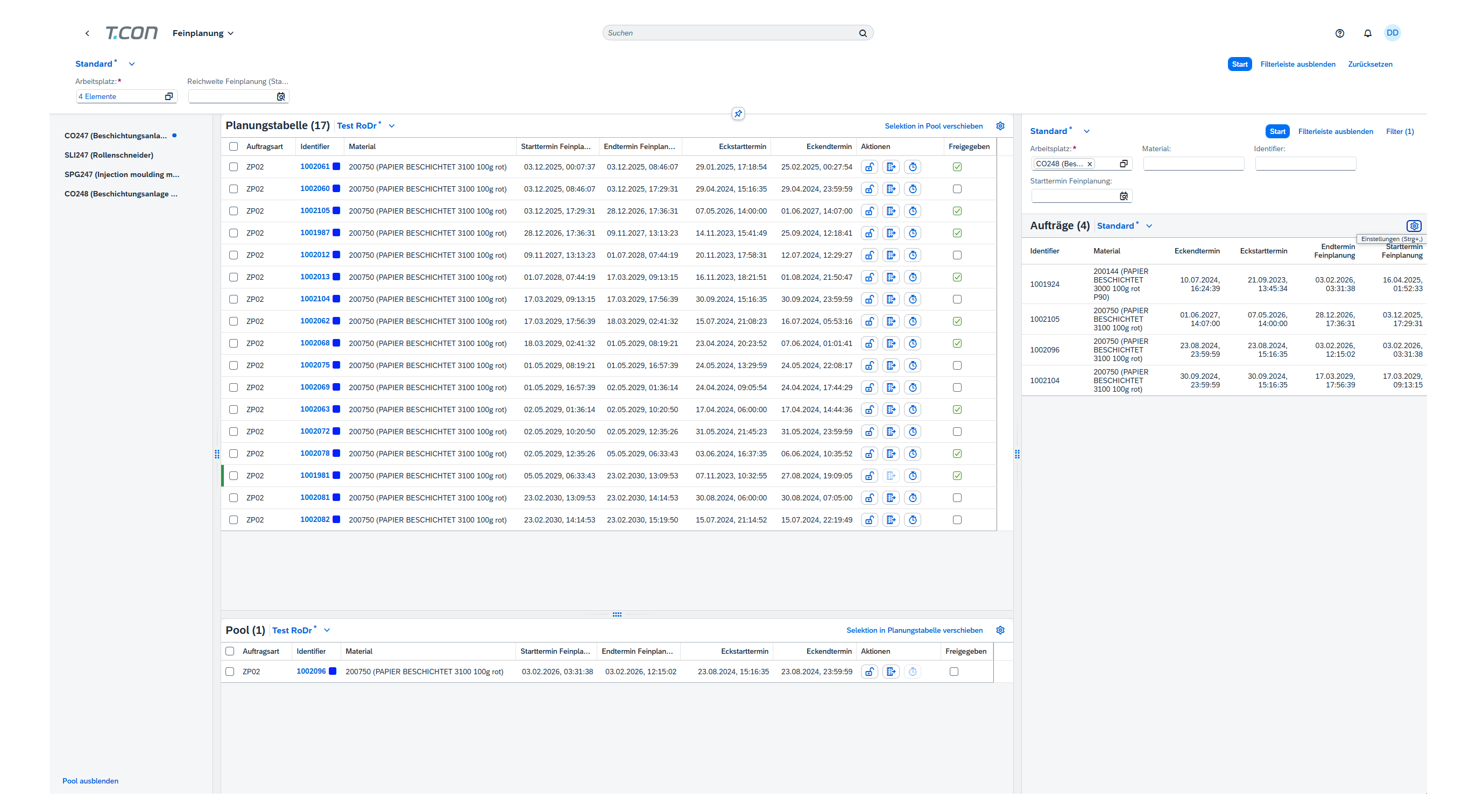

Choosing the right components

MES CAT 7 PRIVATE is structured by default in four modules. You decide which features you need. We’ll work with you every step of the way, as well as pulling in consulting and solutions architects for technical details. Together, we’ll find the right solution for your production flow.

Framework program, planning, warehouse, production, and HU cockpits. Available on-premises or for cloud operation.

Integration components and functions

Analytics at shop floor and enterprise levels. Reports, 360-degree production order analytics, including quantities, waste, defects, energy, etc.

Automated factory self-testing and error detection, as well as QM laboratory tests

Modularity and scalability:

flexible and fit for the future

MES CAT is built on a modern, API-based architecture – a far cry from rigid monolithic designs. The modular structure gives you maximum flexibility, and allows your system to grow with you, at your pace. Migration to the cloud can take place at any time, and new applications can be seamlessly integrated through the APIs. We want you to have a MES that is fit for the future and adapted to your enterprise – not the other way around.

Greater user-friendliness and connectivity

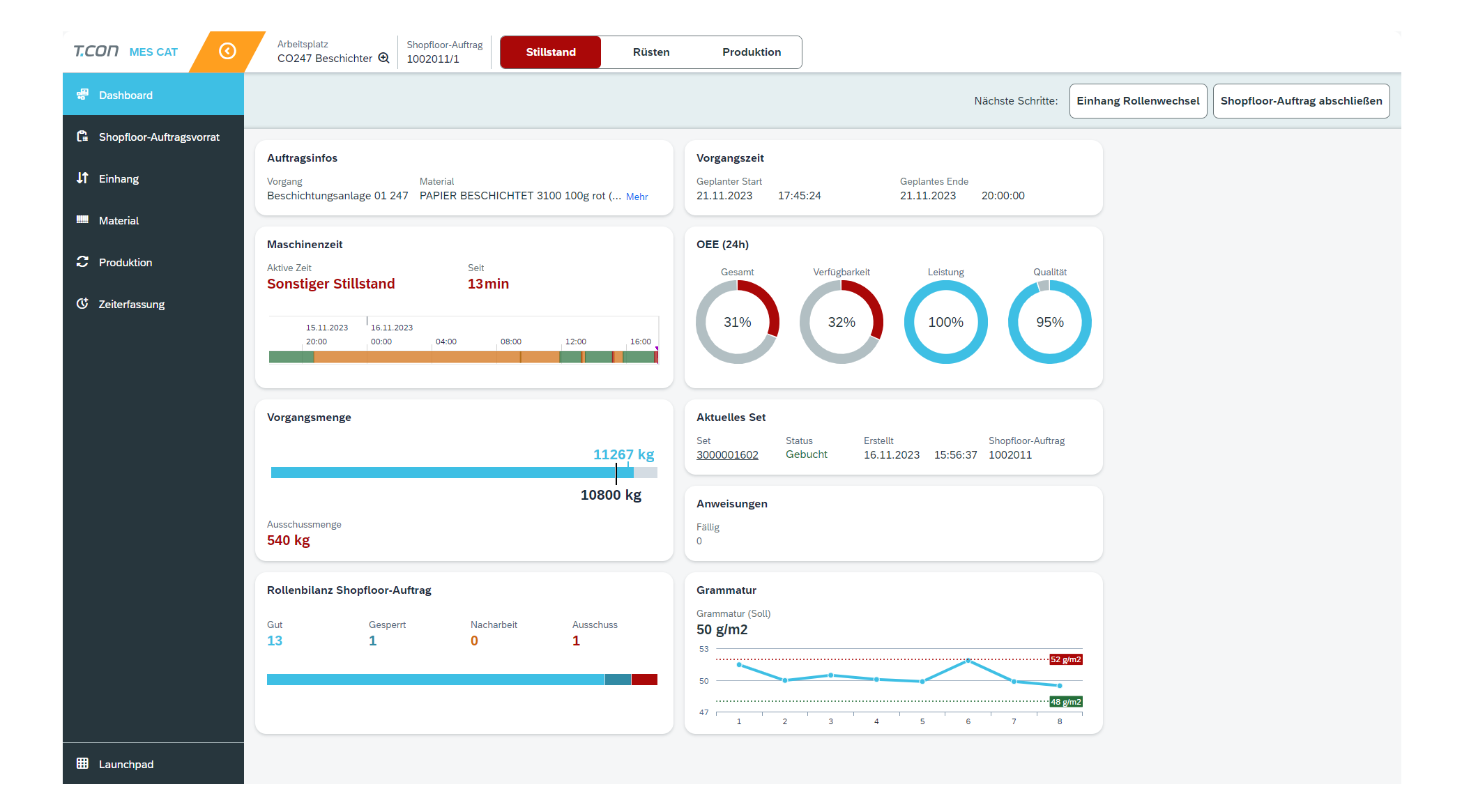

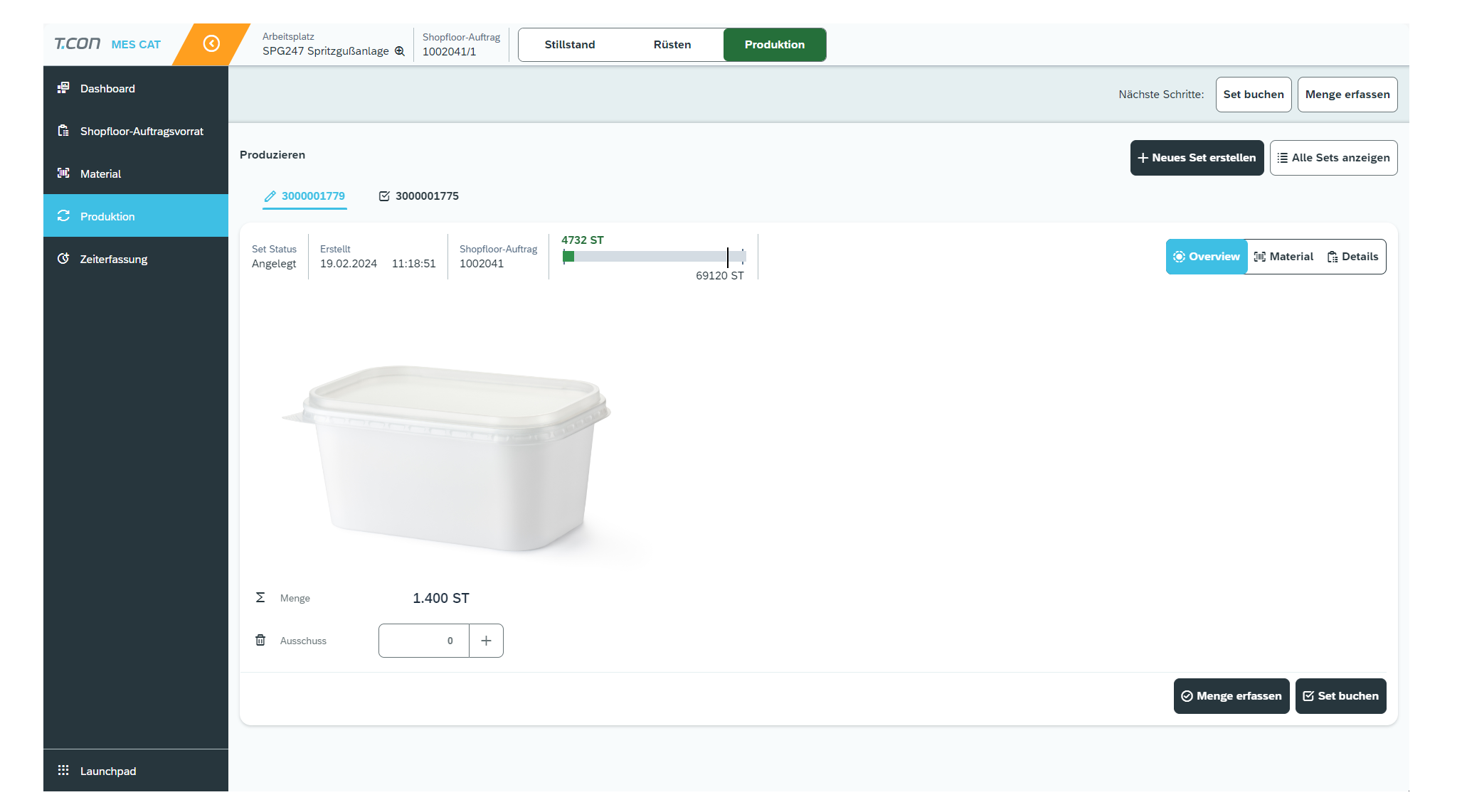

The latest version 7 of T.CON's successful MES CAT application not only marks the dawn of the cloud-native era, but also puts the worker more firmly in the spotlight thanks to the latest UI and AI features.

More focus on workers

-

Supportive UI concept

For smoother interaction between people, systems, and machines. -

Push notifiactions instead of searching for data

Thanks to seamless machine connectivity and automatic, event-driven alert functions for workers. - Tailored to area-based manufacturing

Functions and language are precisely tailored to your requirements. -

Modern UI5 design

The intuitive user interface ensures maximum ease of use.

In a technical sense, even better than before

- Hybrid-friendly design

Whether cloud, on-premise, or both: thanks to API-based design, the choice is yours - Ready for the future

The core functions are already in the BTP cloud – for long-term security and scalability - Full compatibiliy

MES CAT 7 works seamlessly with older releases and third-party shop floor solutions