What TRIM SUITE can do for you?

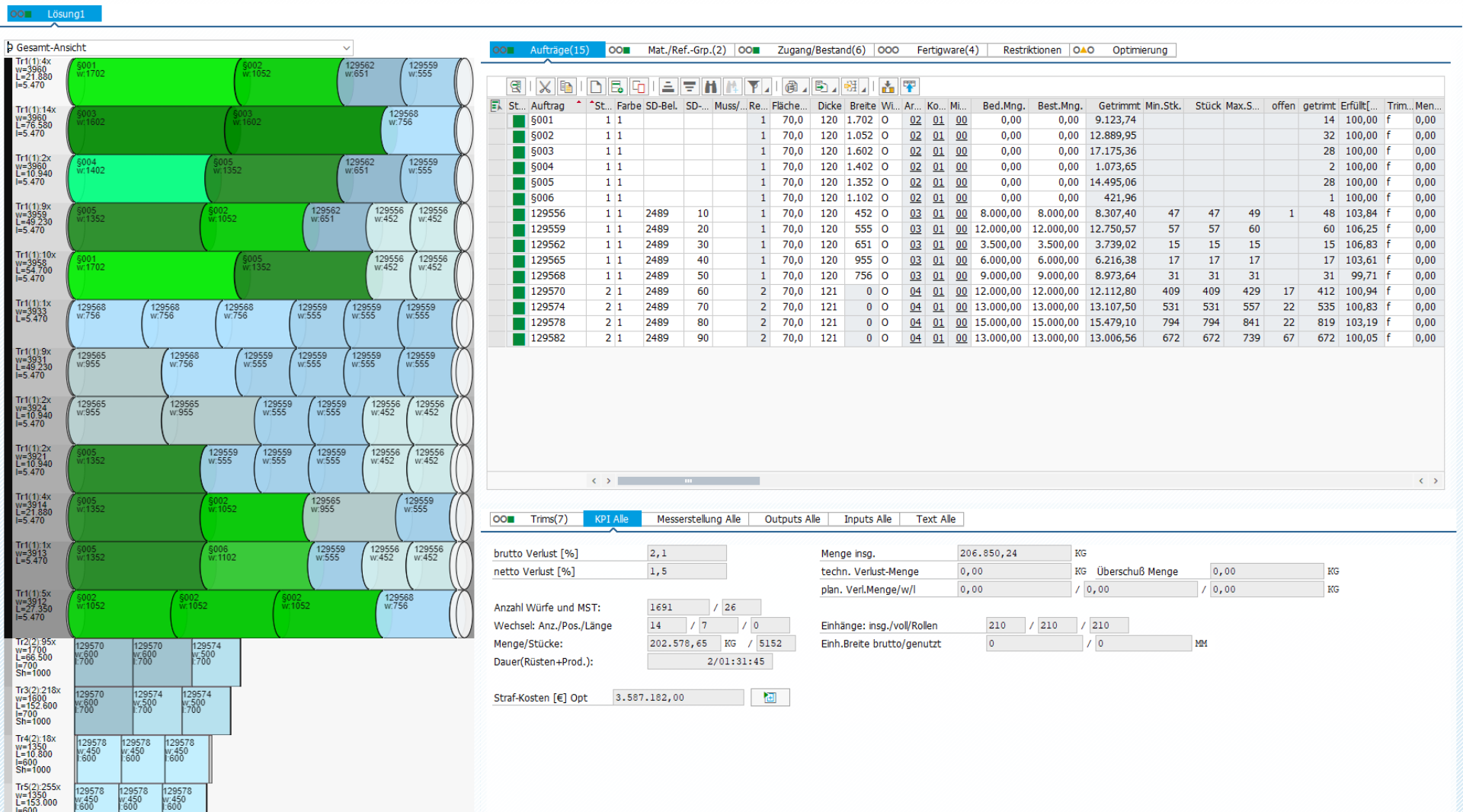

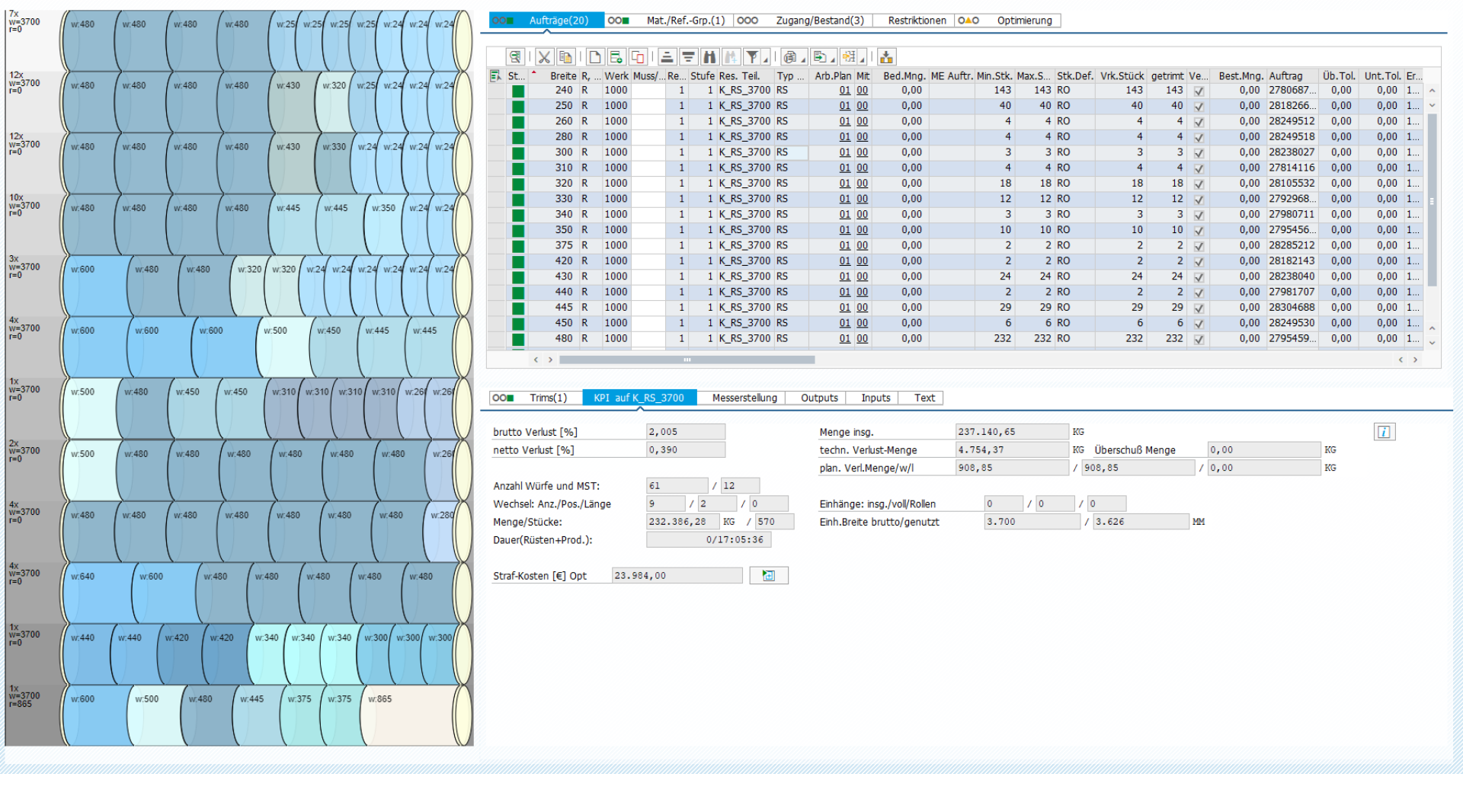

Cutting plans offer significant savings potential in area-based manufacturing. Manual creation is time-consuming and often leads to more waste and longer setup times.

Familiar technology and easy handling

TRIM SUITE by T.CON is fully integrated into your SAP planning tools. Sophisticated functions can be customized to your specific requirements and revolutionize your processes: multi-target calculation in seconds and intuitive operation. This makes detailed planning efficient and easy.

- Reduce storage costs and increase profitability

- Keep an eye on production processes and avoid errors

- Simple and intuitive operation

- Optimize production times, minimize planning times, and reduce setup times

- Reduce scrap and conserve resources

Feature highlights

It’s never too late with HOT TRIM

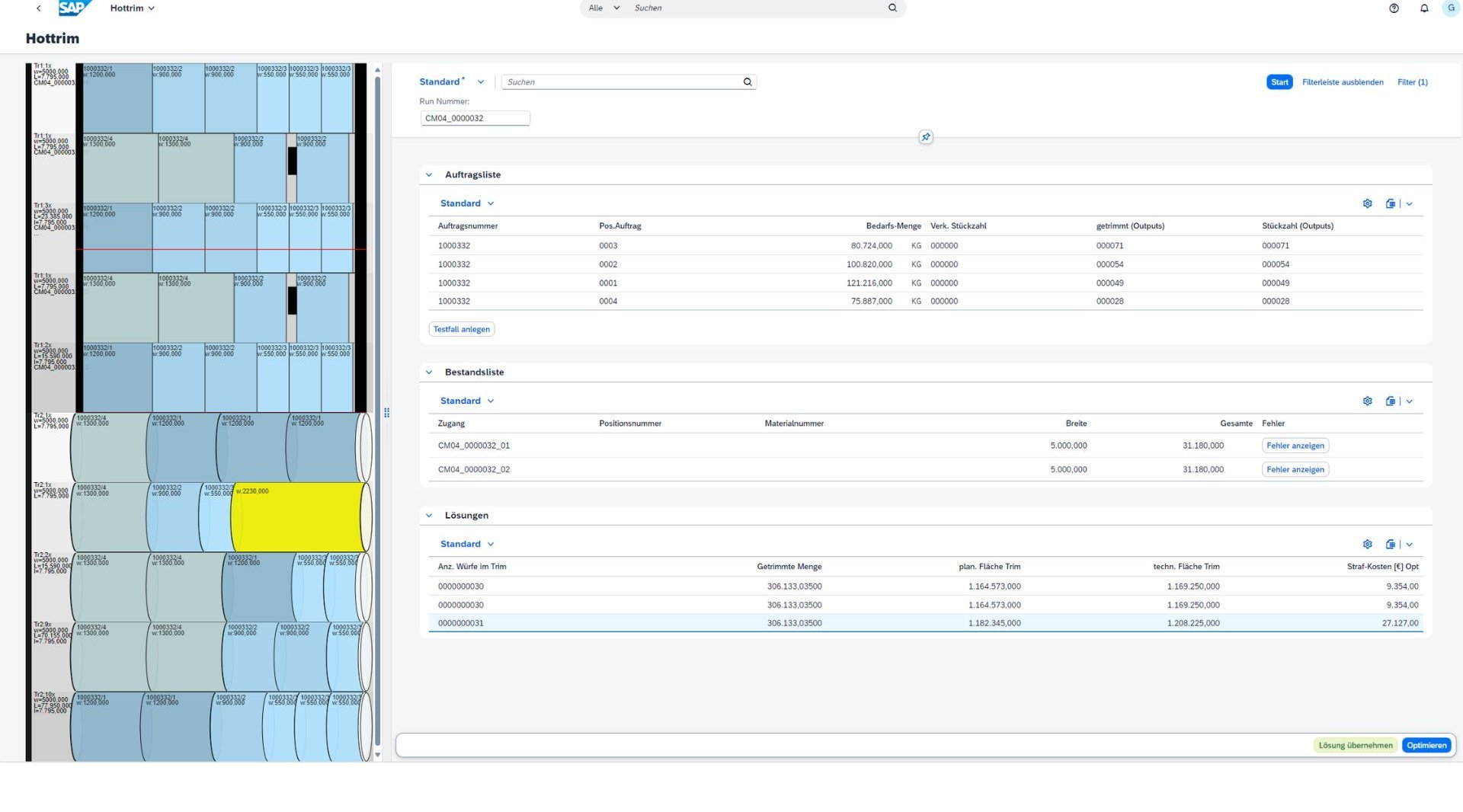

Even the best-laid plans of mice and men sometimes go awry. And that means that cutting plans may need to be modified on the fly. HOT TRIM, easy to use with its modern UI5 interface, is the perfect way for workers to make changes even when production is already underway.

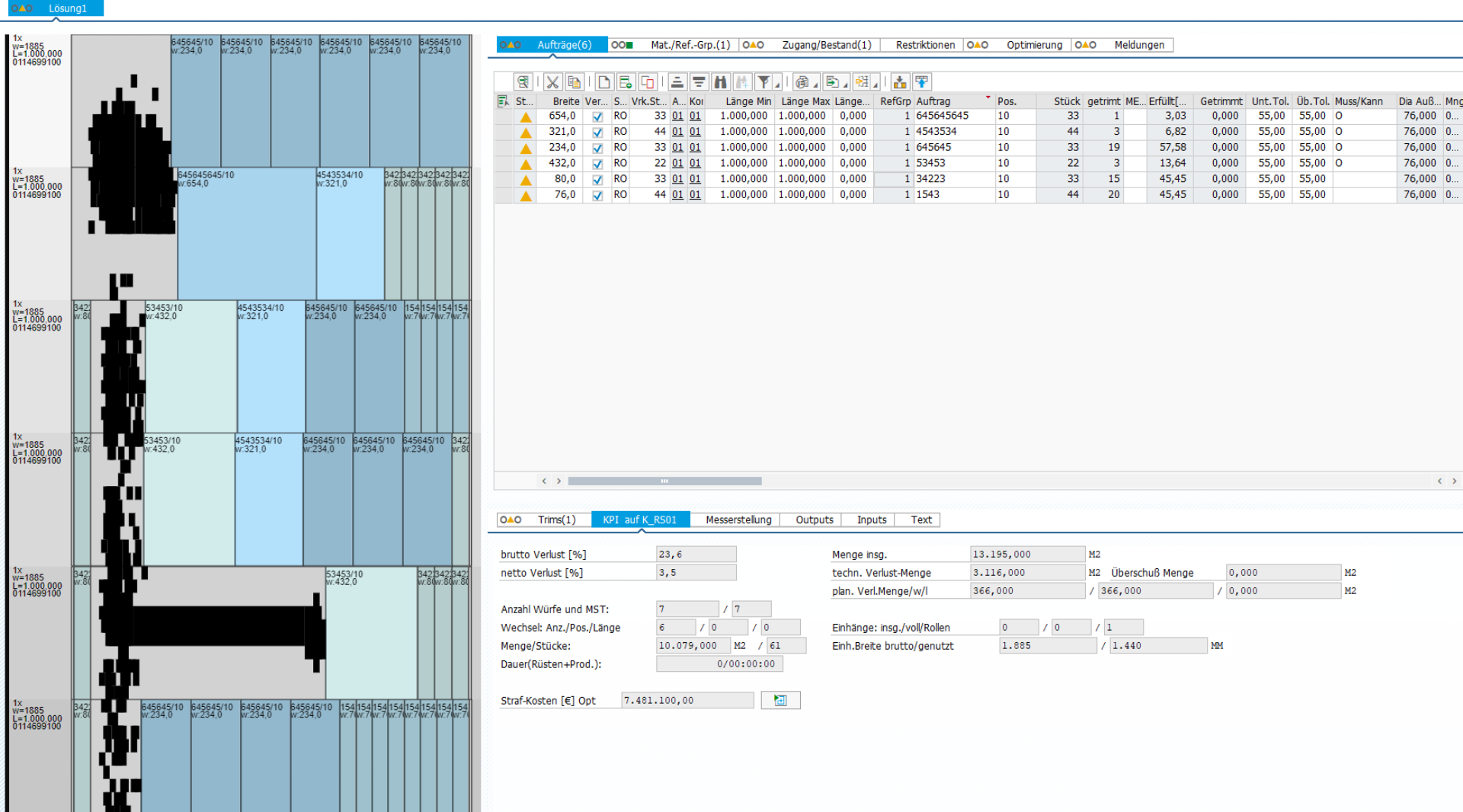

Maybe there’s an issue with the machine settings. Maybe the raw materials vary in quality. For whatever reason, defects can sometimes occur, particularly when manufacturing intermediate products. Modern systems log these variations in quality digitally and record them as supplementary information.

Now QUALITY TRIM can use this data to automatically “plan away” the issues in the cutting plans, and thus ensure a perfect end product – every time.

Automatically correct defects with QUALITY TRIM

Snip by snip to sustainability

A successful roadmap for the digital transformation in production systems, with networked IT and OT, must cover the route end-to-end. Even a small cog in the wheel, such as trim optimization, can be an important factor for the big picture. The cherry on the cake: profitability inevitably goes hand in hand with sustainability! And with TRIM SUITE, that’s no pipe dream.

- Less waste

- Shorter setup times

- More products in the same amount of time

- Lower storage costs

- Fewer rejects

The perfect component

for SAP-based trim optimization

It’s almost impossible to visualize modern sheet-based production without trim optimization. There are many and varied solutions, but the majority are costly, complex, and challenging to integrate into your SAP systems... thus dragging down profitability. TRIM SUITE by T.CON is different. TRIM SUITE is 100% SAP-native, with the corresponding enhanced technology and familiar intuitive UX. At the same time, it features carefully designed functionality perfectly tuned to your needs.

TRIM SUITE pays off twice over

- Ready to use within days

- Affordable

Product preview

Discover the whole world of T.CON modularity

However, outstanding solutions also require outstanding experts in industry processes. And people with whom you can discuss matters on an equal footing. At T.CON, you get both. For the TRIM SUITE, but also for many other solutions for your industry.